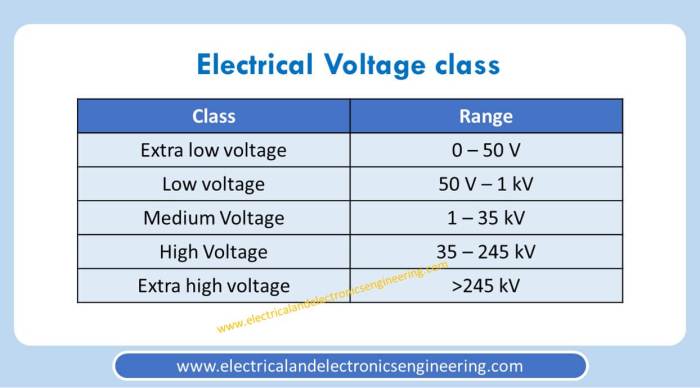

Voltages of 600v or more are – With voltages of 600V or more taking center stage, this article embarks on an electrifying journey into the realm of high-voltage systems. From their applications in industries to the safety measures they demand, we unravel the complexities of these powerful currents.

High voltages play a crucial role in modern electrical systems, offering both benefits and challenges. Their use in power transmission, industrial machinery, and medical equipment showcases their versatility and significance.

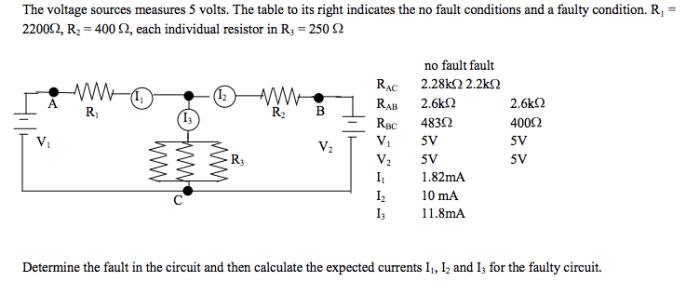

Understanding High Voltages

Voltages of 600V or more are significant in electrical systems due to their increased potential for causing harm. They are commonly found in industrial and commercial settings, as well as in certain household appliances.

High voltages can pose significant hazards, including electrical shock, burns, and even death. Therefore, it is crucial to take appropriate safety precautions when working with or around high-voltage systems.

Potential Hazards of High Voltages

- Electrical Shock:High voltages can cause severe electrical shocks, which can lead to muscle spasms, burns, and cardiac arrest.

- Burns:Electrical arcs and sparks generated by high voltages can cause severe burns to the skin and underlying tissues.

- Electrocution:In extreme cases, high voltages can cause electrocution, which is a fatal electrical shock.

Safety Precautions for Working with High Voltages

- Training and Qualification:Only trained and qualified personnel should work with high-voltage systems.

- Personal Protective Equipment (PPE):Wear appropriate PPE, including insulated gloves, safety glasses, and protective clothing, when working with high voltages.

- Grounding and Bonding:Properly ground and bond all equipment and components to prevent electrical shocks.

- Lockout/Tagout:Follow lockout/tagout procedures to isolate and de-energize equipment before working on it.

- Testing and Inspection:Regularly test and inspect high-voltage systems to ensure they are operating safely.

Applications of High Voltages

High voltages are utilized in a diverse array of industries and applications, enabling efficient power transmission and operation of specialized equipment. These applications include:

Electrical Power Transmission

High voltages, ranging from hundreds of thousands to millions of volts, are employed in long-distance power transmission systems. This allows for efficient transmission of electricity over vast distances with minimal energy loss due to resistance. Substations transform high voltages to lower levels for distribution to homes and businesses.

Voltages of 600v or more are considered hazardous and require special handling. While we’re on the topic of history and exploration, have you heard about the war of 1812 scavenger hunt ? It’s a fascinating way to learn about the past.

Anyway, back to electrical safety, remember to always consult a qualified electrician when dealing with high voltages.

Industrial Applications

High voltages are used in various industrial processes, including:

- Electric arc furnaces:High voltages create intense heat for melting and refining metals.

- Electrostatic precipitators:High voltages remove particulate matter from industrial emissions.

- High-power lasers:High voltages generate the energy required for laser operation.

Medical Applications

High voltages are used in medical equipment such as:

- X-ray machines:High voltages generate X-rays for medical imaging.

- Radiation therapy:High voltages accelerate electrons or X-rays for cancer treatment.

- Pacemakers:High voltages power the electrical pulses that regulate heart rhythm.

Electrical Components for High Voltages

High voltage systems demand specialized components capable of withstanding extreme electrical stresses. These components are meticulously designed and constructed, considering crucial factors such as insulation, conductors, and switches.

Insulation

- Insulation materials play a vital role in high voltage components, preventing current leakage and ensuring safe operation. Common insulators include porcelain, glass, and composite materials, each offering unique advantages and applications.

- Insulator design must consider voltage levels, environmental conditions, and mechanical stresses. Proper insulation thickness and shape are essential to prevent electrical breakdown and maintain system integrity.

Conductors

- High voltage conductors are typically made of copper or aluminum, known for their excellent conductivity and ability to withstand high currents.

- Conductor design involves careful consideration of cross-sectional area, insulation, and cooling mechanisms to minimize losses and ensure reliable performance.

Switches, Voltages of 600v or more are

- Switches are critical components in high voltage systems, allowing for circuit interruption and isolation. They must be capable of handling high currents and voltages safely.

- High voltage switches employ specialized designs, such as vacuum interrupters or sulfur hexafluoride (SF6) gas insulation, to achieve reliable switching operations.

Electrical Safety Practices

Working with high voltages of 600V or more requires strict adherence to safety regulations and practices. Proper training, protective equipment, and maintenance procedures are crucial for preventing electrical accidents and ensuring the safety of personnel.

Training and Qualification

- Thorough training is essential for understanding the hazards associated with high voltages, proper handling techniques, and emergency procedures.

- Only qualified and experienced personnel should be authorized to work on high-voltage systems.

- Regular refresher training and updates on safety regulations are necessary to maintain competence.

Protective Equipment

Appropriate personal protective equipment (PPE) must be worn to minimize the risk of electrical shock, burns, or other injuries.

- Insulated gloves, sleeves, and coveralls

- Safety glasses or face shields

- Non-conductive hard hat

- Insulated footwear

Maintenance and Inspection

Regular maintenance and inspection of high-voltage equipment are essential for ensuring its safe operation.

- Inspect equipment for damage, corrosion, or loose connections.

- Test and calibrate protective devices, such as circuit breakers and ground fault interrupters.

- Maintain a clean and dry work environment.

Emergency Procedures

Emergency procedures must be established and communicated to all personnel.

- Know the location of emergency shutdown buttons and isolation switches.

- Have a plan for rescuing injured personnel from energized equipment.

- Train personnel on CPR and first aid for electrical injuries.

Measurement and Monitoring of High Voltages: Voltages Of 600v Or More Are

Measuring and monitoring voltages of 600V or more require specialized instruments and techniques to ensure accuracy and safety. These methods are essential for maintaining electrical safety and preventing accidents.

Instruments for High Voltage Measurement

High voltage measurements are typically performed using specialized instruments such as:

- High voltage probes

- Voltage dividers

- Digital multimeters with high voltage measurement capabilities

- High voltage oscilloscopes

Measurement Techniques

Various techniques are employed to measure high voltages safely and accurately:

- Non-contact methods:Using capacitive or inductive sensors to detect the presence of high voltage without making direct contact.

- Contact methods:Using high voltage probes or voltage dividers to measure the voltage directly.

- Oscilloscope measurements:Using high voltage oscilloscopes to capture voltage waveforms and analyze their characteristics.

Safety Considerations

Measuring and monitoring high voltages requires strict adherence to safety protocols:

- Use properly rated instruments and protective gear.

- Follow lockout/tagout procedures to isolate the circuit.

- Maintain a safe working distance from high voltage components.

- Wear appropriate personal protective equipment (PPE), such as insulated gloves and arc-rated clothing.

By employing appropriate instruments, techniques, and safety measures, accurate and safe measurement of high voltages can be achieved, ensuring electrical safety and preventing potential hazards.

Design Considerations for High Voltage Systems

Electrical systems operating at voltages of 600V or more require meticulous design and adherence to best practices to ensure safety, reliability, and efficiency. This section explores the fundamental design principles and considerations for high voltage systems.

Key factors to consider include voltage drop, insulation coordination, and grounding. By addressing these aspects effectively, engineers can design high voltage systems that meet the demands of various applications while mitigating potential risks.

Voltage Drop

Voltage drop is the reduction in voltage that occurs as electricity flows through a conductor. In high voltage systems, minimizing voltage drop is crucial to ensure that equipment receives adequate voltage for proper operation.

- Factors affecting voltage drop include conductor size, length, and material.

- Proper sizing and selection of conductors is essential to minimize voltage drop within acceptable limits.

Insulation Coordination

Insulation coordination involves selecting and applying insulation materials to prevent electrical breakdown and ensure the integrity of the system. In high voltage systems, insulation must withstand high electrical stresses and prevent flashovers and short circuits.

- Factors considered in insulation coordination include insulation type, thickness, and coordination with other system components.

- Proper insulation design ensures reliable operation and minimizes the risk of electrical accidents.

Grounding

Grounding provides a low-resistance path for fault currents to flow, protecting equipment and personnel from electrical shocks and damage. In high voltage systems, effective grounding is essential for safety and system stability.

- Grounding systems must be designed to handle the potential fault currents and provide a safe path for their dissipation.

- Proper grounding reduces the risk of electrical accidents and ensures the reliable operation of the system.

FAQ Section

What are the potential hazards associated with high voltages?

High voltages can cause severe electrical shocks, burns, and even death. They can also damage equipment and start fires.

What safety precautions should be taken when working with high voltages?

Proper training, protective equipment, and maintenance procedures are essential when working with high voltages. Lockout/tagout procedures, grounding, and regular inspections are crucial for ensuring safety.

What are some common applications of high voltages?

High voltages are used in power transmission, industrial machinery, medical equipment, and scientific research.